Types of Steam Trap Available

For many individuals and businesses the minefield that is “types of steam trap” can be a difficult problem, the answer being looked for is from so many choices of types of steam trap which is the one best suited for my process or application. We hope that in this blog we offer your business the best possible explanation in plain language to ensure that all your future choices on steam traps are the right ones on every occasion. The reason that care is needed when choosing which type of steam trap to use is the fact that if you make the wrong choice the consequences can result in poor efficiency, water hammer issues, increased costs and in some extreme cases complete failure of an entire process. The latter is the experience of one of our customers some years ago when they were badly advised by one of our competitors. For a complete guide of the do’s and don’ts of steam trapping please continue to read our Blog or for specific steam trap issues please contact us.

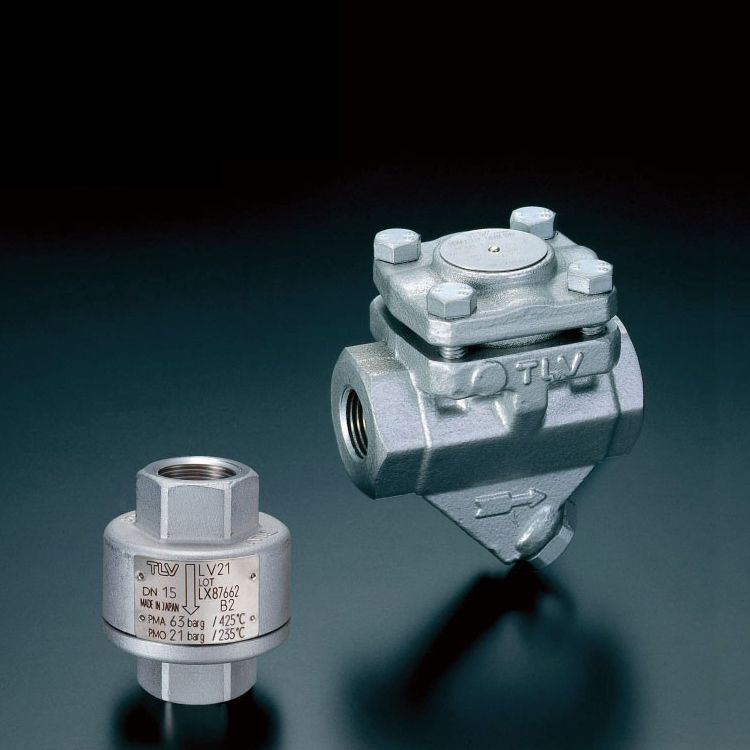

Types of Steam Trap Free Float

The TLV Free Float Steam Trap is one of the most efficient types of steam trap available at present, a simple design offering excellent process efficiency with orifices sizes to suit any pressure or application, for example, the all stainless steel TLV J3SX Free Float Steam Trap is available with a 2, 5, 10, 14 and 21 bar orifice and if you’re not sure what orifice your steam trap should have contact us and we will provide your business with the right advice and information based on your system and process. For a full guide to free float steam trap technology please follow the highlighted link and download the latest information.

Free float types of steam traps are suitable for most process steam applications such as steam coils, Thermoliers, plate heat exchangers, tube-in-tube heat exchangers, boiling pans, cylinder dryers, and laundry applications to name just a few. When free float steam trap is fitted with a steam lock release or lock release valve they are very efficient on corrugator plants, in our own experience we have seen production outcomes improve with one of our customers due to lock release valves fitted to the TLV SJ5FNX-14 Free Float Steam Trap and a degree of steam trap monitoring. This unique situation in our experience in process steam has seen increased energy efficiency and a fall in production costs that we believe cannot be repeated by other equivalent but inferior steam trap technology. For more information on how Besseges (VTF) Ltd and TLV technology can help your company achieve better outcomes please contact us to discuss your requirements.

Types of Steam Trap Line Drainage Applications

For many years the options on line drains on process steam lines have been limited to what can be considered as 20th Century technology a typical example is the old faithful Thermodynamic Steam Trap. Since the days of the cotton revolution in the North of England, these steam traps have air locked on start-up so engineers have come up with several methods to resolve the issue, these ranged from hitting the steam traps with mallets and hammers, loosening off the trap cover and installing the steam trap upside down to name but a few. I have to say that steam trap manufacturers have improved thermodynamic steam traps in many ways, Spirax Sarco added grooves across the disc surface to bleed air and in some cases for rapid air release a hole is drilled in the disc but both of these methods have the same outcome, steam leaks. From our perspective, the most ingenious method to solve this age-old problem came from TLV, they added a bimetallic ring which allows air to release rapidly from the system until the trap temperature reaches 100°C, then the bimetallic ring expands and falls away allowing the disc to seal until it’s next operation. In the case of the bimetallic ring, this does not operate again until the next start-up cycle, simple but very effective just like so many TLV products.

Types of Steam Trap Free Float Line Drain

The real revolution in line drain types of steam traps has come in the guise of the free float line drain from the excellent TLV. This range of efficient steam traps has many advantages over the Thermodynamic Steam Trap, including bimetal air release technology and because it isn’t a cycling steam trap rapid condense removal on system start-up. A further advantage over thermodynamic types of steam traps is the allowance to install free float line drains on shallow dirt pockets, our experience of this with some of our customers has reduced water hammer issues substantially on start-up. Depending on the size of your steam lines there is a large range of free float line drains available from Besseges (VTF) Ltd and TLV, for more information or to enquire about stock availability please contact our sales team. If you’re unsure of which types of steam trap will suit the needs of your site our technical sales team is always happy to help and can be contacted by clicking any of the highlighted contact links on this Blog. For further insights into process steam take the time to explore our many blogs.

Register For An Account

Save & manage your details, access invoices, and enjoy a quicker shopping experience!