TLV Pressure Reducing Valves Efficient Reliability Assured

Here at Besseges (Valves, Tubes & Fittings) Ltd we have supplied TLV pressure-reducing valves for the past 16 years and in our experience this range of products offers the absolute assurance of efficient reliability compared to any other product we have come across in our time as a distributor of process steam products. In the days before we became a TLV pressure-reducing valve distributor we offered our customer base Spirax Sarco products but a bad experience with one of their representatives led us to seek another process steam product and at that time we were unaware of the TLV product range.

After some research and discussion, we were offered the opportunity to become one of the first independent TLV distributors in the United Kingdom and from that day to this we have never looked back. Since that time we have become one of the most recognised TLV distributors in the North of England and as well as offering the TLV pressure-reducing valves we carry in stock a full range of free float steam traps, thermodynamic steam traps, thermostatic steam traps, condense pumps and many other process steam products. The rest of this Blog will open your eyes to the efficient reliability of TLV pressure-reducing valves, exploring the entire TLV range available, please take the time to continue reading by clicking read more or if you are looking for a quicker route for more information on TLV pressure reducing valves please contact our excellent technical sales team.

TLV Pressure Reducing Valves COSR Range

The TLV range of COSR pressure-reducing valves is available as COSR-3, COSR-16 and COSR-21 depending on your primary pressure requirements. They come in three materials, cast iron GG25, ductile cast iron GGG40 and cast stainless steel A351 Gr CF8, threaded versions come in 15mm to 25mm and flanged versions from 15mm to 150mm apart from the stainless version which is only available flanged from 15mm to 50mm.

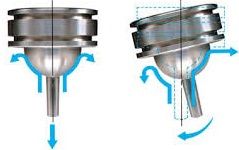

The COSR TLV pressure-reducing valves are a self-actuated pilot-operated unit with very accurate process steam control. All TLV pressure-reducing valves in this range come with a self-aligning shock-absorbing spherical piston, all major internal parts are manufactured from stainless steel to extend service life, an integral strainer for the pilot valve extends trouble-free service, internal secondary pressure sensing makes external sensing unnecessary and larger COSR TLV pressure reducing valves are fitted with a silencer for noise reduction.

The design of the self-aligning piston was a result of observing a table tennis ball in a stream of air, this simple experiment opened the door to advances in pressure-reducing valve technology not found in any other manufacturers’ products making TLV pressure-reducing valves the world leader in process steam control. This same technology can now be found in process steam control valves available as the CV COSR and the CV Cospect please contact us for more information on this or any of our process steam products.

TLV Pressure Reducing Valves COS Range

This excellent range of TLV pressure-reducing valves has all the features mentioned in the previous paragraph with one important difference, the COS range of valves comes complete with a built-in separator and integral free float steam trap, as with the COSR range they are available as the COS-3, COS-16 and COS-21. This revolution in process steam technology will remove 98% of entrained and non-discharged condense from your process steam lines. This efficient condense removal could improve heat transfer efficiency by up to 9%, reducing your costs while ensuring you get the best out of the process steam produced. Please take note though that these savings and increases in heat transfer efficiency can be easily undone by the lack of or poorly installed insulation.

Uninsulated steam mains can increase condense production by an enormous 90%, a massive waste of steam energy paid for by your business. Returning to TLV pressure-reducing valves the COS range with built-in separator, strainer and TLV free float steam trap is a must for improved heat transfer, as far as we are aware this is the only pressure-reducing valve available in the world that can cover its own cost over time, this is achieved by firstly as we discussed by removing condense from your process steam but in addition with a built-in steam trap, the condense is then returned automatically to your Hotwell via your condense return system.

This is one of the best pressure-reducing valves available on the market today and because of the design of the valve body is one of the easiest to maintain. You can remove portions of the TLV pressure-reducing valves to maintain in the workshop without removing the entire valve from the steam line. This allows easy access to the Pilot Valve assembly, separator and steam trap without too much of a fuss. I have witnessed the staff of TLV distributors strip down and reassemble this unit in less than 15 minutes, if you can find a competitor valve that you can achieve the same with please take the time to comment on this Blog or any of our informative blogs or contact our technical sales team today.

TLV Pressure Reducing Valves DR20 Direct Acting

The DR20 range of TLV pressure-reducing valves are direct-acting units suitable for steam and compressed air, the valve is highly efficient and robust and will do smaller steam loads at a 30/1 reduction rate with a maximum primary pressure of 16 bar. The DR20 range of TLV pressure-reducing valves is available in threaded or flanged connections sizes 15mm (½”) to 25mm (1”) covering secondary pressures 0.14 to 2 bar DR20-2, 1.8 to 6 bar DR20-6 and 5.4 to 10 bar DR20-10, all these versions are available from our stock.

To size your requirement download the data sheet which has the sizing chart and flow graph for this stainless constructed range of TLV pressure-reducing valves, pressure-reducing stations play an important role in your process steam efficiency. Process steam run at higher pressures reduces pipe sizing on site allowing higher volumes to be transported to where they are required. On small processes, the DR20 is an invaluable tool to reduce steam pressure and increase heat transfer efficiency, ideal for small heater batteries, steam coils, Thermoliers, small roller driers and many other processes.

You will find TLV pressure-reducing valves on food processing sites, laundries, rubber processing, and textiles everywhere efficient heat transfer is a must should the main be process steam and always TLV for efficient reliability, contact us for TLV pressure-reducing valves or any other process steam ancillary from the world leader in process steam technology TLV and of course their North of England Distributor Besseges (Valves, Tubes & Fittings) Ltd.

Get started in seconds!

Save your details, view past orders, and enjoy a faster checkout every time.