TLV COS-R Pressure Reducing Valves for Steam

There are many types and manufacturers of pressure-reducing valves but in our opinion, there are none to match the efficiency and quality of the TLV COS-R pressure-reducing valves range. This high-quality quality innovatively designed product offers a long life, easy maintenance and excellent control characteristics. TLV has been a leader in innovation in process steam since the 1960s offering the free float steam trap, the TLV COS-R pressure-reducing valves and cyclone separators to name but a few.

The development of the TLV COS-R pressure-reducing valve range was a long and extensive process; one of the most exceptional developments with this valve was the inclusion of a shock-absorbing spherical piston unique to TLV products which ensures the TLV COS-R pressure-reducing valves accurately maintain set pressure, reacting quickly to primary pressure and or flow fluctuations. For more information on how this product can aid your process steam system please take the time to read the rest of this Blog by clicking read more or if you haven’t the time contact our technical sales team to discuss your requirements.

TLV COS-R Pressure Reducing Valves Features

As discussed already the TLV COS-R pressure-reducing valves have a shock-absorbing spherical piston which was developed on principles similar to those that keep a table tennis ball centred in air flow. The shape was reproduced within the TLV COS-R pressure-reducing valve product allowing the piston to constantly self-centre in steam flow, this action reduces fluctuations in steam flow through the pressure-reducing valve and accurately maintains set pressure. This is the key to ensuring process steam heat exchangers receive controlled unimpeded steam flow best suited for each application.

Pressure-reducing valves that have a standard flat piston are subject to the ravages of a water hammer resulting in inaccurate pressure control and poor flow characteristics, a fluctuation pressure gauge can often characterise this. We believe that to ensure accurate steam pressure and flow control, businesses should always use the TLV COS-R pressure-reducing valves where applicable. Other great features of this product include internal sensing, wide pressure adjustment and inbuilt Teflon seals which are reusable, unlike many other manufacturers where gasket kits are required each time a pressure-reducing valve is serviced and usually comes at a great expense. For more information on this or any other TLV steam products please contact our sales team.

TLV COS-R Press Reducing Valves Installation

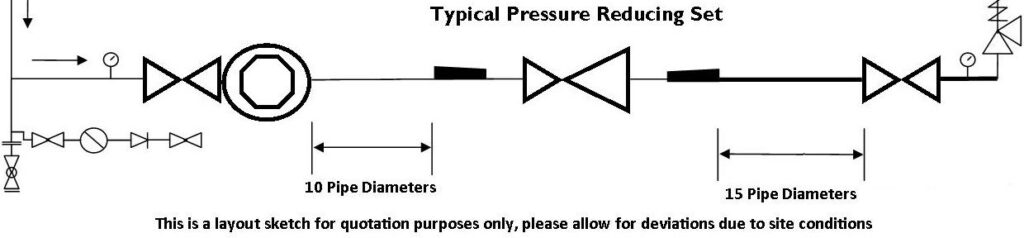

Installation of pressure-reducing valves should always be done according to the manufacturer’s guidelines, failure to adhere to the correct installation procedure can and often will affect the efficiency of the valve. TLV COS-R pressure-reducing valves should be installed with a ten-pipe diameter free run before the reducer and fifteen pipe diameters after. This should be measured from the strainer on the inlet side to the installed eccentric reducer and following the outlet eccentric reducer to any installed product. For example, this would include any stop valves, gauges, and or safety valves.

The diagram below illustrates this and we can provide a guide to suit any installation, please contact us for more information. What you have to understand about installing pressure-reducing sets is that every time you reduce the free run of pipework, you will always affect the efficiency of the installation and reduce the optimum steam flow to your process. You will notice we also mentioned installing eccentric reducers before and after the reducing set, this is because if a concentric reducer of any type is installed this becomes a collection point for condense to pool.

If this occurs’ an increase in instances of water hammer damage is inevitable, as the condense pools behind a concentric reducer this enters the steam flow becoming entrained condense. When TLV COS-R pressure-reducing valves are installed this is deflected by the curved piston. Still, on a valve with a flat piston, this does cause the piston to become offset eventually and reduces flow control and pressure reduction efficiency. But, even the service life of the TLV product is affected by poor installation which results in increased maintenance and a shorter service life. For more information or to discuss your particular installation please contact us.

TLV COS-R Pressure Reducing Valves Innovation Continues.

TLV has now produced a new control valve which uses the same innovation as is part of the TLV COS-R pressure reducing valves range. The TLV CV COS-R is a control valve which uses the same curved piston to deflect the water hammer and ensure excellent steam flow control in addition the latest version of this highly thought of product has a steam trap outlet built in. This allows condense to be drained directly from the underside of the control valve thus increasing heat transfer and process efficiency. If you would like a demonstration of this latest breakthrough in process steam technology please contact us and wherever you are we can arrange this for you.

Besseges (Valves Tubes & Fittings) Ltd are becoming synonymous with process steam efficiency and TLV and we look forward to hearing from your business, please talk to our excellent technical sales team and ask about the TLV COS range of pressure-reducing valves with built-in cyclone separators and free float steam trap. In addition, the TLV COS pressure-reducing valve with its built-in separator and steam trap will increase heat transfer efficiency by up to 9% by removing 98% of entrained condense, our next Blog on process steam will cover this unique and excellent product.

Register For An Account

Save & manage your details, access invoices, and enjoy a quicker shopping experience!