TLV COS Pressure Reducing Valves

Buying the right pressure-reducing valve for steam systems is a minefield; there are so many products available that choosing the right one must seem impossible. Every business that offers a pressure-reducing valve for steam will tell you their product is the market leader based on price, quality and any number of reasons. My personal favourite is the price question due to the fact if a business bases the efficiency of their process steam system on price alone; their engineering or maintenance department plays second fiddle to accounts.

A pressure-reducing valve in a process steam system plays a vital role in controlling steam pressure and flow to heat exchangers that are usually at the heart of production; the efficiency of the heat exchanger can mean the difference in production quality and the time required to manufacture. The simple fact is if a distributor or manufacturer offers you equipment that is ridiculously cheaper than its closest rival then in our opinion you are getting an inferior valve. If you would like to know why we believe so completely in the TLV COS pressure-reducing valves take the time to read this blog or contact our technical sales team to discuss your requirements.

TLV COS Pressure reducing Valves Efficient Control

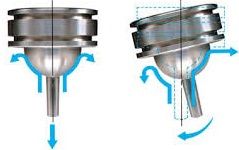

The TLV COS pressure-reducing valve stands out from other similar products for several reasons the first being the unique spherical piston; which the design of was a huge milestone in process steam technology. The piston design results in better flow control and is self-centering when the stem becomes misaligned; the unique design eliminates turbulent steam flow characteristics and due to the fact the piston will self-align it offers another unique solution to the problems associated with water-hammer. Installation of this product offers accurate steam pressure and excellent flow characteristics with the additional bonus of dryer steam due to the built-in separator and free-float steam trap.

TLV COS Pressure Reducing Valves Energy Efficiency

Another unique feature of this excellent product is the fact that the TLV COS pressure-reducing valve has a built-in separator and steam trap. The built-in cyclone separator removes up to 98% of the condense contained in the steam flow including entrained condense which can’t be removed by the installation of dirt pockets. The removal of the entrained condense in particular increases heat transfer efficiency on steam injection and heat exchanger systems, a TLV cyclone separator can increase heat transfer efficiency by 9% and in our opinion is the only product of its kind available that can reduce energy costs.

It stands to reason that an increase in heat transfer efficiency will reduce steam consumption over time although at present to the best of our knowledge, this premise has not been tested by the manufacturer or independent body. But based on our experience with customers that have used the TLV COS pressure-reducing valves many agree with our opinion on this subject.

TLV COS Pressure Reducing Valves Installation Advantages

TLV COS pressure-reducing valves offer a unique installation advantage when a separator is pivotal to process efficiency, other manufacturers of pressure-reducing valves will offer a separate valve and separator so the advantage is clear straight away. Two separate items take longer to install, take up more room and require more support brackets; in addition, a stand-alone separator requires the installation of a steam trap to remove the condense, a third aspect of the installation and further time. Other advantages include when replacing an existing pressure-reducing valve of the same bore size TLV COS pressure-reducing valves will fit perfectly in an existing installation adding the efficiency of a separator without making major alterations to existing pipework.

Another reason to install TLV COS pressure-reducing valves is the advantages concerning maintenance; like the majority of TLV equipment this valve is fitted with inbuilt Teflon seals allowing the valve to be taken apart in situ and put back together without the requirement of purchasing a gasket kit each time this is required; this can be done up to seven times as long as the TLV guidelines are followed. The following list of clear advantages to this product is the reason that cost is an illusion when installation time and process efficiency are the primary goals.

- Efficient and precise flow control

- Accurate and precise pressure control

- Dryer steam with increased heat transfer efficiency

- Self-aligning piston reduces water hammer issues

- Space saving

- Reduced installation costs when compared to alternatives

- Does not require a gasket kit every time it is serviced or cleaned

- Easy maintenance due to design excellence

- Built-in separator and free-float steam trap

To close this latest blog please consider when you next buy a pressure-reducing valve for your process steam system what the true costs are of installing the cheaper alternative. What you save initially will soon be eroded by increased maintenance costs, no possibility of increased energy efficiency, higher installation costs (compared to installing three pieces of equipment to a single valve) and the assurance of TLV quality compared to many other manufacturers.

We believe that TLV COS pressure-reducing valves are in the vast majority of installations the only alternative that should be considered, the simple truth is in nearly all scenarios you get what you pay for and anything else is just a false economy. Please contact us to discuss all your process steam requirements, we are one of the North of England’s leading steam specialists and authorised TLV Distributors; we look forward to hearing from you.

Register For An Account

Save & manage your details, access invoices, and enjoy a quicker shopping experience!