TLV COS Pressure Reducing Valves

TLV is one of the market leaders in process steam technology offering a range of products with unique qualities and design features. One of their most prolific products is their pressure-reducing valves and in particular the COSPECT series of products. Also known as TLV COS pressure-reducing valves; this unique and efficient range of valves comes complete with a built-in cyclone separator and free-float steam trap. Comparing this single item to a standard pressure-reducing valve installation offers space-saving and vastly reduced installation time. When another manufacturer’s pressure-reducing valve is used and a separator is required; three pieces of equipment have to be installed the pressure reducer itself, a separator and a steam trap. The extra pipework support required alone increases installation time, space and costs. For an alternative continue to read this blog on the TLV COS pressure-reducing valves or contact us.

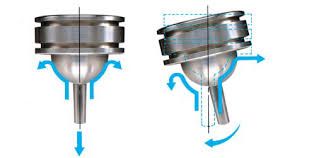

TLV COS pressure-reducing valves across the whole COS and COSR ranges are supplied with a self-aligning piston; this unique technology deflects the water hammer and reduces turbulence within the steam flow ensuring very accurate pressure and flow control. This astute advance in steam flow control was based on the simple principle of a table tennis ball in airflow; if you look at a table tennis ball in a flow of compressed air you will see that the ball centres itself in the airflow constantly. When you view a self-aligning piston in a cut-off of any of the TLV COS pressure-reducing valves you can see the same shape machined at the base of the piston, with the added spring on the piston rod ensuring the piston is always returned to the correct position. Accurate steam flow control and constant pressure is key to efficient heat transfer and in the next paragraph, we explore the other key feature a built-in cyclone separator.

TLV COS pressure-reducing valves across the whole COS and COSR ranges are supplied with a self-aligning piston; this unique technology deflects the water hammer and reduces turbulence within the steam flow ensuring very accurate pressure and flow control. This astute advance in steam flow control was based on the simple principle of a table tennis ball in airflow; if you look at a table tennis ball in a flow of compressed air you will see that the ball centres itself in the airflow constantly. When you view a self-aligning piston in a cut-off of any of the TLV COS pressure-reducing valves you can see the same shape machined at the base of the piston, with the added spring on the piston rod ensuring the piston is always returned to the correct position. Accurate steam flow control and constant pressure is key to efficient heat transfer and in the next paragraph, we explore the other key feature a built-in cyclone separator.

TLV PRV’s – Energy Efficient

One of the unique features of these particular TLV COS pressure-reducing valves is the built-in cyclone separator first incorporated into the valve in 1966. The cyclone separator removes entrained and non-discharged condense from the steam flow within the valve itself and the built-in free-float steam trap does the rest. The unit removes 98% of condense from the steam flow increasing heat transfer efficiency by up to 9% and although there have never been any studies done on this; it stands to reason that this will offer a reduction in energy consumption compared to using a standard pressure-reducing valve. It is our honest opinion based on nearly two decades of experience with TLV COS pressure-reducing valves that these products should always be used on suitable installations. The initial cost of these products is an investment in process steam efficiency which will ensure accurate pressure control, accurate flow control and increased heat transfer efficiency. For more information on product or sizing, contact our technical sales team who will work with you to satisfy the needs of your process; we look forward to hearing from you.

One of the unique features of these particular TLV COS pressure-reducing valves is the built-in cyclone separator first incorporated into the valve in 1966. The cyclone separator removes entrained and non-discharged condense from the steam flow within the valve itself and the built-in free-float steam trap does the rest. The unit removes 98% of condense from the steam flow increasing heat transfer efficiency by up to 9% and although there have never been any studies done on this; it stands to reason that this will offer a reduction in energy consumption compared to using a standard pressure-reducing valve. It is our honest opinion based on nearly two decades of experience with TLV COS pressure-reducing valves that these products should always be used on suitable installations. The initial cost of these products is an investment in process steam efficiency which will ensure accurate pressure control, accurate flow control and increased heat transfer efficiency. For more information on product or sizing, contact our technical sales team who will work with you to satisfy the needs of your process; we look forward to hearing from you.

Disclaimer: Information correct at the time of publishing (June 2016) but is subject to change. E&OE.

Register For An Account

Save & manage your details, access invoices, and enjoy a quicker shopping experience!