Steam Traps & Dirt Pockets, the solution to better quality steam.

As a business, we are heavily involved in discussing with our customers the best use of some of our products about their steam systems. We supply many process steam-related products and in particular, are an official TLV steam products distributor. Process steam efficiency can be a very involved process and ensuring the best and most efficient use of the equipment we supply is a key part of our relationship with our entire process steam customer base. In recent months we have worked with a well-known food manufacturing site to improve the efficiency of some of their cooking processes using various products including steam traps. For more information on our experiences with this business please read on or contact us.

Steam Traps & Dirt Pockets and their role in process efficiency.

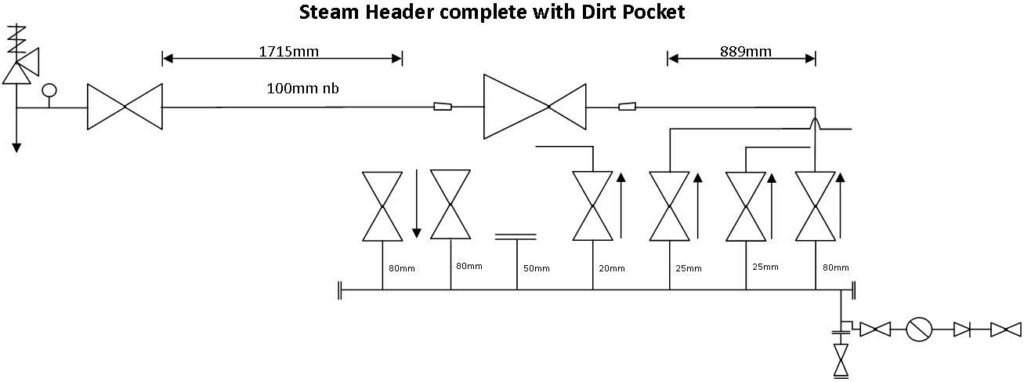

One of the simplest and most effective routes to improve steam quality in your system is the correct use of dirt pockets in their various forms. When considering the placement of a dirt pocket in your process steam system, not only should you install effective and efficient steam traps but also the placement and size of the dirt pocket play a huge part in process efficiency. For example, you can fit the best steam trap available on your system but if the dirt pocket it is connected to is ineffective due to size and position then you will have wasted your money. Worse than this is to not fit any dirt pockets at all thus ensuring that your steam will be filled with condense (water), scale and other foreign objects which will ensure your heat transfer efficiency will be greatly diminished and increased water hammer damage will increase maintenance costs.

So how do you ensure that what you have is going to give you the best possible results, most of the advice we give our customers and their Engineers is common sense and once we have discussed the issues with them you can be assured of better quality steam now and in the future, obviously this occurs when our advice is followed.

There are three main types of dirt pockets we see used by steam users these are the standard dirt pocket, a relay-point dirt pocket and line-end dirt pocket. Each of these should be installed to a fixed dimension depending on the line size and should be fitted with a complete steam trap set consisting of a line drain steam trap, non-return valve, stop valves, optional sight glass and line end dirt pockets should be fitted with an air eliminator. With certain types of steam traps, minimum dimensions between the steam trap and the non-return valve are required. For further information on this please contact us.

Returning to the local food manufacturing site we discussed earlier, in recent months we have visited this site on several occasions to resolve issues on water hammer and process efficiency. We have also furnished them with a complete report on some of the major problems they have dealt with due to some very poor installations that had been done in the past. The first part of the work to put this right was done recently with the repositioning of a dirt pocket and the installation of a new relay point dirt pocket. Since this work was completed one department on this site has reported that the process times have improved by 8 minutes on each cook. This increase in efficiency will be the result of improved process steam quality due to a reduction in condense (water) in the steam line, which will have improved heat transfer.

If you feel that your steam system is not as efficient as you believe it should be please contact us at Besseges (Valves, Tubes & Fittings) Ltd for advice on the latest products, we can offer steam traps, stop valves, actuated steam valves, control valves and many other steam ancillaries to suit your needs. We have decades of experience in the supply of steam traps and other process steam products and we are certain that your business will benefit from opening an account with Besseges (Valves Tubes & Fittings) Ltd for all your valves & pipeline requirements please contact us. While visiting our Website take the time to use our TLV Engineering Calculator where you can explore other ways of improving your process steam system.

Register For An Account

Save & manage your details, access invoices, and enjoy a quicker shopping experience!