Steam Trap Selection for Process and Heating Installations

When selecting a steam trap for a particular process many businesses will look at the price rather than the specific product they are buying and on the face of it those companies will have saved some money on the initial cost. Equally, in some cases, the business is given poor advice by suppliers who frankly just don’t have a clue about the product they are selling. The key to process efficiency is the correct selection of steam traps, an issue that we can help you with ensuring you have the right steam trap with a correctly sized orifice when applicable. For more information on steam trap sizing and the consequences of poor steam trap selection please contact our sales team or click the read more icon for more information on the steam trap selection.

Steam Trap Selection

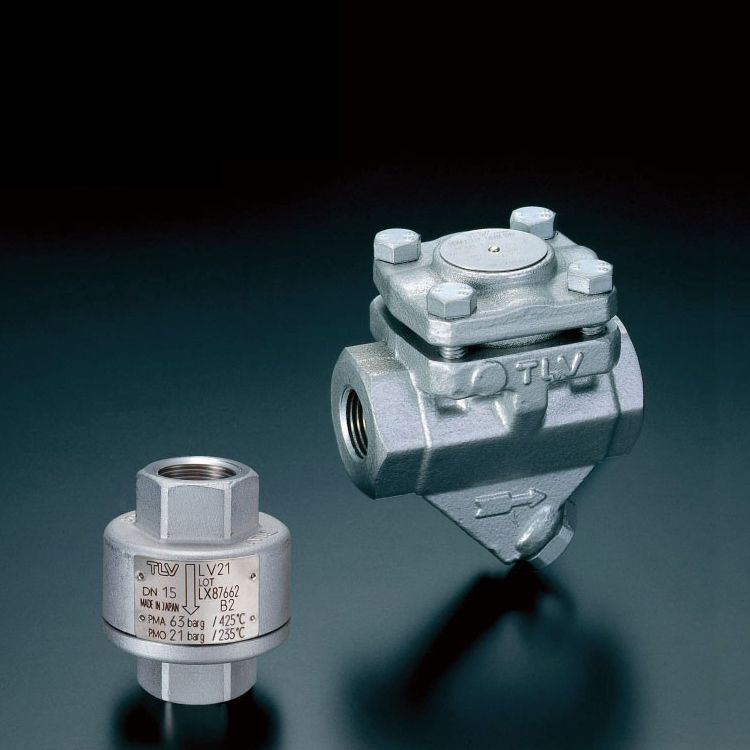

When selecting a steam trap for a process or heating application unless you are aware of all the facts and understand how to evaluate the requirement it is usually best to talk to your local TLV Distributor or TLV themselves. If you are confident that your business has the relevant knowledge to evaluate the criteria required then please use the following guidelines to aid in the task of steam trap selection.

- Determine the condense discharge requirement of the process and select the matching steam trap consider whether it a hot or sub-cooled.

- Select the steam trap according to the operating pressure, temperature, orientation and all relevant process and installation conditions.

- Calculate the condense load requirement and apply the manufacturers recommended safety facture. Consider the application in normal working load and start up requirements as these will differ.

- Calculate the differential pressure to ensure the correct orifice size is selected where relevant to the steam trap type.

- Consider whether air binding or steam locking could affect the efficient operation of the selected steam trap.

- Consider the life cycle costs of the selected steam trap to ensure process and cost efficiency are balanced. (In other words, saving money on the initial cost of a steam trap will not always result in long-term gains)

When all the above have been considered and you disregard your accountant’s view that by buying the cheaper model or type of steam trap will save your business money, in most cases the majority of site engineers can remember the last time they bought the cheaper alternative and the consequences. The long-term goal when selecting the correct steam trap is process efficiency and cost-effectiveness, this achievement can only benefit the process in hand and the consequences of poor steam trap selection can be far-reaching and result in hidden costs you may not have even considered. For examples of the consequences of poor steam trap selection please contact us or read our next Blog on process steam.

Register For An Account

Save & manage your details, access invoices, and enjoy a quicker shopping experience!