Steam Traps and the prevention of Steam Locking

Recently we were contacted by a customer with temperature fluctuation issues at his laundry site, the issue had occurred on a Calender dryer where they were getting regular temperature fluctuations and asked us if we could resolve this issue for them. The problem occurred due to a condition on some process steam systems known as steam locking. If you would like further information on steam locking and steam lock release using the right steam trap please read on.

What causes steam locking?

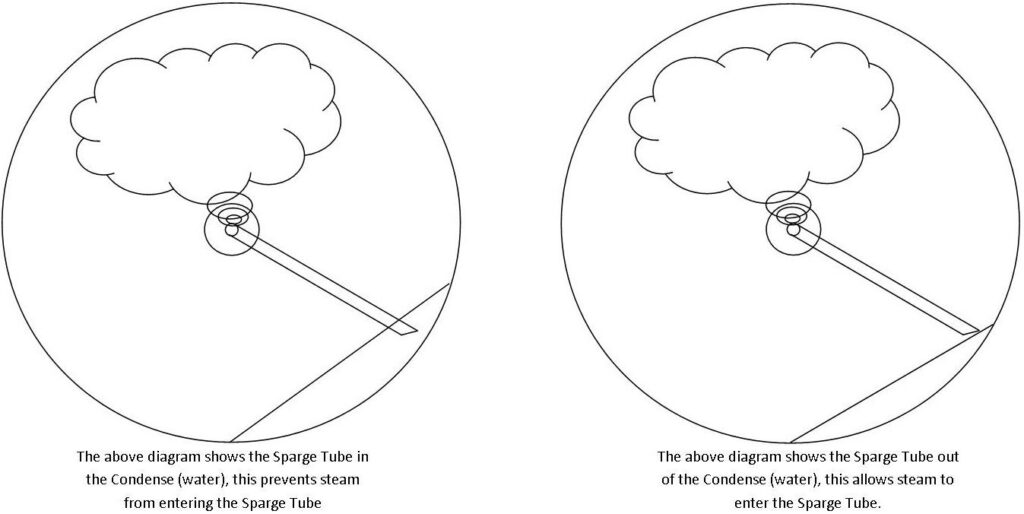

Steam locking is not caused by the steam trap but by the design of the equipment it is installed on. In the case of the specific customer we visited over the temperature fluctuations on his steam equipment, the type of Laundry Calender dryer they were using was the older version with steam-heated rollers. This type of steam Calender removes condense (water) via a sparge tube which because of the movement of the roller, passes in and out of the condense flow allowing process steam to pass into the tube. See Diagrams below.

The steam in the sparge tube then prevents the steam trap from releasing condense (water) because as the description suggests a steam trap is exactly that. Until the steam before the trap condenses the steam trap remains closed trapping the condense (water) in the sparge tube and the roller in position and so cooling the process down. In the case of the customer we discussed earlier, when the issue was resolved the temperature at the steam trap outlet increased by between 11 and 24’C. This would then ensure that the temperature of the rollers was increased and remained consistent.

Steam Traps to Prevent Steam Locking

The solution to this form of steam locking is simple and cost-effective and makes use of the air release technology found in all forms of TLV steam traps. By fitting a steam lock release valve to the top of the steam trap which is a mechanism that once set will use the air release capsule to release the steam by allowing it to leak through it. This can be set after the steam trap has been installed or in some cases can be retrofitted to some TLV steam traps. The procedure for setting these lock-release devices can be done by any competent engineer or if preferred can be set by your TLV representative or distributor representative.

We would also recommend that whilst doing this procedure you monitor your Steam Trap temperature as this will give you a guide to the optimum setting of the lock release valve and ensure that steam locking will no longer affect your process temperatures. This was done at our customer’s site after we had supplied the TLV J3X free float steam traps with LRV, at their request we set the lock release valves using a PocketTrapman. A device normally used for testing steam traps for leaks also has an inbuilt temperature probe but any suitable temperature probe will do the job.

So please contact Besseges (Valves, Tubes & Fittings) Ltd for this type of problem on your steam system or for any information on valves, pipework or fittings because as our logo states “For All Your Pipeline Requirements” means exactly what it says. Your business can contact us with confidence and the certainty that your needs and requirements will be met by a company committed to the best possible service and the understanding of your process issues to ensure we deliver the right product.

Register For An Account

Save & manage your details, access invoices, and enjoy a quicker shopping experience!