Grooved Pipe and Fittings a Wartime Invention

Grooved pipe and fittings were first used as early as 1917 and invented by a Royal Engineer, Lieutenant Ernest Tribe in conjunction with Dr Henry Hele-Shaw; originally known as the Victory Joint. The sad truth is they were originally developed for use on semi-portable flamethrowers used in battles during World War 1.

It was found that many semi-portable flamethrowers had faulty connections; which when they failed covered the operators with burning liquid. A clever engineer Ernest Tribe looked at how the connections could be made more secure and improve the efficiency of the equipment.

Grooved Pipe and Fittings Improves Horrific Killing Machine

In conjunction with a hydraulics specialist Dr Henry Hele-Shaw, Lieutenant Tribe perfected a flexible coupling that prevented joint failure. Thus, improving the efficiency of a horrific killing machine and preventing injury to its operators. Weapons like the Vincent Battery Semi-Portable Flame Thrower and others like it were used on the battlefields of the First World War. They were more efficient and as many as 50 were deployed during the second half of this deadly conflict. Weapons like these had been used by German forces since 1914 and often those troops that did operate this and similar equipment; were executed immediately if they were captured, their captors often using the captured flamethrowers as the instrument of death.

In conjunction with a hydraulics specialist Dr Henry Hele-Shaw, Lieutenant Tribe perfected a flexible coupling that prevented joint failure. Thus, improving the efficiency of a horrific killing machine and preventing injury to its operators. Weapons like the Vincent Battery Semi-Portable Flame Thrower and others like it were used on the battlefields of the First World War. They were more efficient and as many as 50 were deployed during the second half of this deadly conflict. Weapons like these had been used by German forces since 1914 and often those troops that did operate this and similar equipment; were executed immediately if they were captured, their captors often using the captured flamethrowers as the instrument of death.

Before we returned to the invention of the Grooved pipe and fittings system, some of the later flamethrowers had a range of 105 to 300 feet. Making them a feared and deadly weapon, which caused fear and panic in the trenches. Usually resulting in many more deaths due to the trench occupants panicking and fleeing the trenches. They were then mown down by gunfire from machine gun positions and snipers, a practice used by both sides during this conflict.

Grooved Pipe and Fittings the Birth of Victaulic

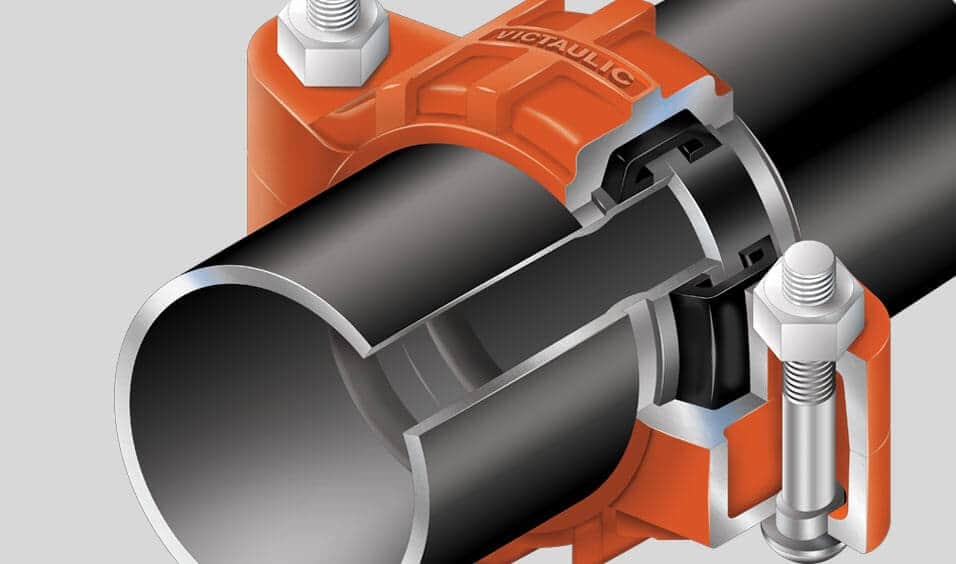

Following the First World War, the Victory Joint took on a new name as its co-inventors chose to name their business Victaulic. A combination of the Victory Joint and hydraulic. So was born the grooved pipe and fittings system that for many years gave the name of Victaulic coupling to the world. The Victaulic grooved pipe and fittings system was the original grooved product; first patented in 1925 it has spawned many similar product lines since.

Following the First World War, the Victory Joint took on a new name as its co-inventors chose to name their business Victaulic. A combination of the Victory Joint and hydraulic. So was born the grooved pipe and fittings system that for many years gave the name of Victaulic coupling to the world. The Victaulic grooved pipe and fittings system was the original grooved product; first patented in 1925 it has spawned many similar product lines since.

Here at ValvesTubesFittings.com, we offer an excellent range of Mech Brand products manufactured by our friends at Jinan Meide; many of you who know our business will be aware we are a distributor of Jinan Meide malleable iron pipe fittings. This trusted brand is one of the Worlds leading casting manufacturers, providing world-class service and quality assurance. Jinan Meide have quality assurance approvals which include ISO 9001:2008 and ISO 14001:2004.

Grooved Pipe and Fittings Approvals

Product approvals for Mech Brand grooved products for the United Kingdom marketplace include Loss Prevention Council Certification (LPC), FM approval and the United Kingdom Kite Mark. The certification associated with these organisations gives great confidence to installers when assuring their customers of a quality build. The Loss Prevention Council have been approving products since 1994 but its history pre-dates the First World War, with the Fire Offices Committee being formed in Manchester in 1909. FM Approval has been around for some time longer with Factory Mutual Laboratories being founded by John R Freeman in 1886, and Kite Marks have been issued since 1945 with the first one being for copper pipe fittings. However, the beginning of the British Standards Institute dates to 1901.

Grooved Pipe and Fittings in a Wide Range of Sizes

Grooved pipes and fittings like so many military inventions are now part of systems that save lives rather than their original intention. Fire sprinkler systems are installed the world over to prevent loss of life and loss of property and can be found in industrial and domestic applications. The grooved products we supply are available across a wide range of sizes from 25mm (1″) nominal bore to 300mm (12″) nominal bore. They can be used in conjunction with our stock pipe in BS EN 10255:2004 25mm (1″) to 150mm (6″) and in larger sizes in the ASTM/API pipeline.

that save lives rather than their original intention. Fire sprinkler systems are installed the world over to prevent loss of life and loss of property and can be found in industrial and domestic applications. The grooved products we supply are available across a wide range of sizes from 25mm (1″) nominal bore to 300mm (12″) nominal bore. They can be used in conjunction with our stock pipe in BS EN 10255:2004 25mm (1″) to 150mm (6″) and in larger sizes in the ASTM/API pipeline.

As well as being able to provide plain-ended and threaded pipe, we can also offer grooved tubes in whatever size you require, grooved tube is not offered from stock, but it is available on relatively short lead times. Delivery can be provided across the United Kingdom on a next-day basis in most cases on orders placed before noon; subject to our standard terms and conditions. Most deliveries from ValvesTubesFittings.com are subject to carriage charges based on weight and dimensions, although on orders over £250 ex VAT delivery is free within the UK mainland. Our carriers do on most occasions offer delivery of 6-metre lengths of tube.

Grooved Pipe and Fittings Product Availability

To explore what we offer in grooved pipe and fittings please look at the following list of grooved products or contact our sales team to discuss your requirements.

- Grooved 90 Degree Elbow

- Grooved 45 Degree Elbow

- Grooved 22.5 Degree Elbow

- Grooved Equal Tee

- Grooved Reducing Tee

- Grooved Mechanical Tee

- Grooved Couplings

- Grooved Tapped Blanks

- Grooved End Caps

- Grooved 11.25 Degree Elbow

- Grooved Concentric Reducer

- Grooved PN16 Flange Adapter

For galvanised grooved pipe and fittings please follow the highlighted link to see the latest available products. For grooved pipe and fittings to suit mechanical systems on non-sprinkler applications; contact our excellent sales team.

Disclaimer: Information correct at the time of publishing (February 2018) but is subject to change. E&OE.

Register For An Account

Save & manage your details, access invoices, and enjoy a quicker shopping experience!