EN 10255 Steel Tube Quality Materials Besseges

EN 10255 steel tube is non-alloy steel suitable and commonly used on fire sprinkler installations, natural gas installations, compressed air pipework, sewage pipelines, process steam lines and many other key processes. Here at Besseges (Valves, Tubes & Fittings) Ltd, we offer quality EN 10255 steel tubes from Cayirova Boru San and Borusan Mannesmann in sizes from 15mm (½”) to 150mm (6”) nominal bore. EN 10255 Steel Tube is available in the United Kingdom in medium and heavy weight with three finishes, which are self-colour, red primer and galvanised, plus the option of being BSP taper threaded or plain ended.

All of these can be offered from our warehouses in Ashton under Lyne for delivery across the UK, some restrictions apply but the majority of our deliveries can be achieved on a next-day basis. Talk to our knowledgeable sales team to discuss your requirements and arrange for delivery to your site or workshop. For more information on the wide range of uses of EN 10255 steel tube please click read more.

EN 10255 Steel Tube Fire Sprinkler Installations

EN 10255 steel tube and similar materials have been used to install fire sprinkler systems in the United Kingdom since the 19th Century. The very first manual sprinkler system was invented by Sir William Congreve in 1812; this was followed by Sir Hiram Stevens Maxim’s automatic sprinkler system installed to protect a furniture warehouse in the mid to late 19th Century until Henry Parmalee installed an automatic fire sprinkler system in 1874 which worked on the principle of solder melting to unplug holes in steel pipe.

The first Henry Parmalee automatic sprinkler system in the UK was installed at John Stones and Company, a cotton spinning mill based in Astley Bridge Bolton. Automatic sprinkler systems were then promoted by the likes of The Mutual Fire Insurance Corporation of Manchester to educate businesses in new technologies that would protect premises and reduce high insurance costs. These same principles are supported by all insurers in the 21st century with over 40 million sprinkler heads installed every year across the world. The automatic sprinkler system was further improved by Frederick Grinnell who originally manufactured the Henry Parmalee automatic sprinkler system, this system is the forefather of the modern systems you see today.

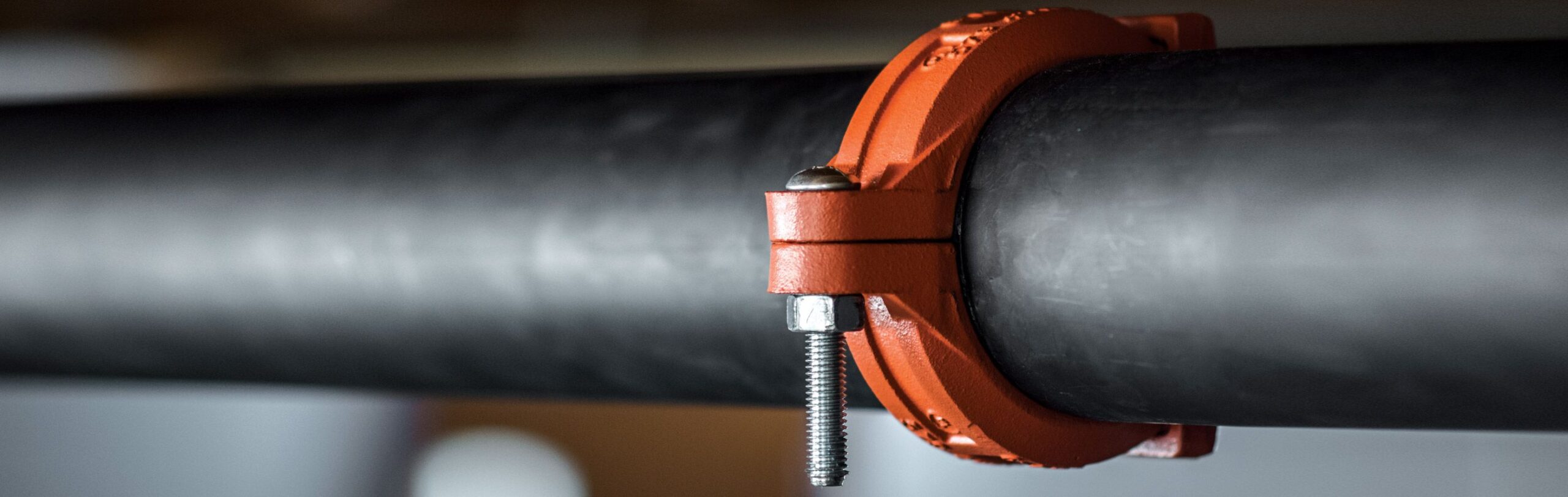

Here at Besseges (Valves, Tubes & Fittings) Ltd and ValvesTubesFittings.com, we offer the material required to install automatic sprinkler systems including EN 10255 steel tubes our blog subject matter today in addition we can also provide malleable iron fittings BS EN 10242:1995, Mech Brand grooved fittings (LPC & FM approved), welding fittings ASME B16.9:2012 & BS EN10253-2:2007, flanges BS10:2009, EN 1092-1:2013-04 & ASME B16.5:2013 and associated sprinkler valves.

EN 10255 Steel Tube Compressed Air Systems

Galvanised EN 10255 steel tube has been used on compressed air systems for many decades but the first version of a compressor was a bellows to increase the heat available to the first metal worker. The First version of the modern compressor was based on the design of the steam engine and produced by the Holman Brothers in Cornwall and known as the Cornish Compressor, these compressors powered the first mining drills which were surprisingly known as The Cornish Rock Drills and were in use across the industrial world in the late 19th century.

The first modern-day screw compressors weren’t manufactured until the 1930s but the first patent for a screw compressor was registered by Heinrich Krigar over fifty years earlier in 1878, it was a long time before manufacturing technology could produce this advanced idea. In the days since the first screw compressors came into general use piping technology has also improved and EN 10255 steel tube in 1938 was listed as BS789:1938 which became BS1387 in 1947 and then BS EN 10255 in 2004.

Here at Besseges (Valves, Tubes & Fittings) Ltd and ValvesTubesFittings.com, we offer excellent quality EN 10255 steel tubes galvanised for use on compressed air systems, this traditional technology has proven itself for decades and your installation can be completed using EN 10255 steel tube, BS EN 10242:1995 malleable iron pipe fittings and Genebre 3020 brass plated ball valves, all these quality products can be purchased by contacting our knowledgeable sales team.

EN 10255 Steel Tube Process Steam Systems

EN 10255 steel tube in heavy grade is used on many low-pressure steam systems; originally steam was a source of power for the growing industries at the beginning of the industrial revolution. The first steam heater was proposed by a gentleman by the name of William Cook in 1745 and by the 1790s pioneers like Mathew Boulton and James Watt had installed steam heating in their homes. These were effectively the first heat exchangers using process steam and their success in an industrial setting was due to the high cost of insurance in the thriving cotton industry at the time. Cotton is a highly combustible material and the use of steam heating using radiators and coil heat exchangers reduced the instances of fires associated with wood or coal stoves.

Advances in the use of process steam carried by EN 10255 steel tube have allowed the industry to use the efficient heat transfer of steam in every conceivable industry across the planet, including food processing, rubber curing, pharmaceuticals, dyeing and finishing and many other heat processes too numerous to mention. Process steam systems rely on good quality EN 10255 steel tubes from Besseges (Valves, Tubes & Fittings) Ltd and others on low-pressure systems, usually not exceeding 10 bar. For higher pressure systems we can offer material in ASTM A106 grade b seamless as an alternative, to explore limitations on pressure and temperature please click EN 10255 steel tube which will take you to a datasheet covering the relevant information. In addition, we have a reputation amongst our growing customer base of being one of the leading lights in process steam installations and can offer a great deal of technical expertise and understanding on the subject of process steam systems and of course EN 10255 steel tube.

EN 10255 Steel Tube and Other Possibilities.

We clearly can’t cover all the possibilities of EN 10255 steel tube in a single Blog but please be assured that the material we offer is of high quality and is manufactured by some of the leading lights in European steel production. Our EN 10255 steel tube in red medium is used widely by installers and fabricators across the United Kingdom and even though there are so many alternatives to this material now it offers an assurance of quality and longevity not yet proven using other methods. We of course offer every possible alternative to EN 10255 steel tube including press-fit and aluminium systems, but we still favour this reliable and efficient product as its track record speaks for itself. Contact us for all your valve and pipeline requirements and we look forward to hearing from you now and in the future, talk to our sales team today.

Get started in seconds!

Save your details, view past orders, and enjoy a faster checkout every time.